Table of Contents

VinaQuartz Mix-Size Supply Strategy is redefining how fabricators achieve profitability and efficiency. For any stone fabricator, profitability isn’t just made in the showroom — it’s made on the cutting table. Every decision, from material nesting to inventory management, directly impacts the bottom line.

This was the daily reality for a leading countertop fabricator in Canada, a company renowned for its craftsmanship but facing hidden inefficiencies that were quietly eroding their profits.

This is the story of how a necessary search for a more reliable supplier, born from frustration with inconsistent quality, led to an unexpected strategic breakthrough. It’s a case study on how a smarter supply chain partnership didn’t just solve a quality problem — it unlocked a new level of operational efficiency and profitability.

The Problem: The Hidden Costs of Inconsistency

The fabricator’s journey began with a growing sense of frustration. Their incumbent supplier, another Vietnam Quartz Slab Manufacturer, was becoming a source of constant uncertainty. Slabs would arrive with noticeable color variations from batch to batch, and occasionally with unexpected blemishes that would force the team to cut around them, wasting valuable material.

This wasn’t just a material issue; it was a reputation risk. Each flawed slab meant a tense conversation with a designer, a potential project delay, and the slow erosion of their hard-earned brand trust, which was built on perfection.

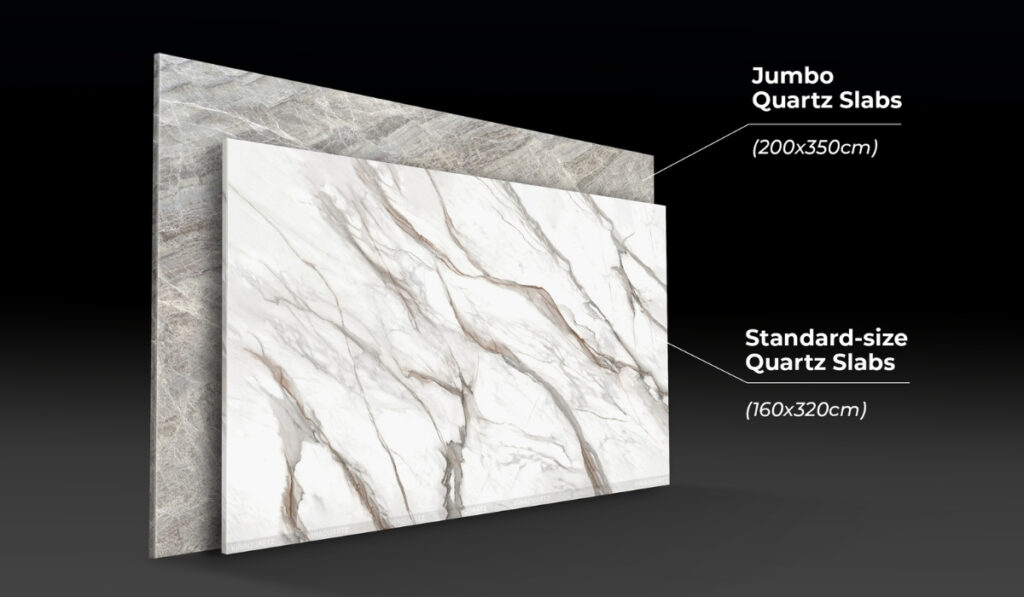

Compounding this quality issue was a second, equally costly problem: a “one-size-fits-all” supply approach. The supplier only offered large, Jumbo quartz slabs. While ideal for large projects, this created enormous inefficiency for a significant portion of their work. They were forced to cut small Bathroom Vanity Top pieces or narrow Backsplashes from massive, expensive slabs. The result was a workshop floor littered with large, unusable offcuts—a daily, physical reminder of wasted money.

The Compounding Effect of Waste on the Bottom Line

The issue was far more profound than just leftover material. It was a compounding business problem. Every square foot of waste represented lost profit. Every oversized slab required more labor to handle and maneuver. Every project required the team to solve complex nesting puzzles on their software, spending valuable time trying to minimize the financial damage of an inefficient slab size.

This constant waste was a silent brake on their growth. It tied up capital in an ever-growing pile of offcuts and prevented them from quoting jobs as competitively as they wanted. They realized their growth was being limited not by their craftsmanship or their sales team, but by their supply chain. They needed more than just a new vendor; they needed a partner who truly understood the business of Quartz Fabrication.

Solution: The VinaQuartz Mix-Size Solution – A Partnership in Efficiency

When the fabricator approached VinaQuartz, our engagement didn’t begin with a price list. It began with questions about their workshop, workflow, and their biggest operational challenges. We identified their two core needs: unwavering quality and a more innovative way to manage material yield.

Based on this understanding, we developed a simple yet transformative solution: the VinaQuartz Mix-Size Supply Strategy.

Instead of a one-size-fits-all approach, we proposed a tailored supply plan that matched the material to the job.

- Jumbo Quartz Slabs (200x350cm) were designated for expansive, seamless Kitchen Island projects, where their size is a distinct advantage.

- Standard-size quartz Slabs (160x320cm) were provided for their smaller, recurring jobs, such as vanities, backsplashes, and shower curbs.

This strategy was elegant in its simplicity. It empowered the fabricator to order the right size for the right job, dramatically slashing waste before the cutting even began. It streamlined their inventory, simplified their nesting process, and had an immediate impact on their material costs per project.

Of course, this intelligent supply strategy was backed by our unwavering commitment to quality. We assured them that every slab, whether Jumbo or Standard, would pass our rigorous multi-point QC process. This guarantee of consistency and perfection eliminated the primary frustration that had initiated their search for a new supplier, creating a foundation of trust from day one.

Watch How VinaQuartz Ensures the Quality of Printed Quartz

The Result: A Trusted Partnership and a More Profitable Workshop

The Canadian fabricator placed a trial order with a mix of both Jumbo and Standard-sized slabs. The impact was immediate and clear. The workshop team found the layouts simpler, the offcut pile shrank noticeably, and the management team saw a direct improvement in the profitability of each job using the standard-size slabs.

The key outcomes of this new partnership included:

- A measurable reduction in material waste, estimated at nearly 20% on vanity and backsplash-heavy projects.

- Increased workshop efficiency, enabling them to complete jobs faster and with greater simplicity.

- The complete elimination of project delays and client complaints related to inconsistent slab quality.

Convinced by the tangible results, the fabricator transitioned their entire quartz supply to VinaQuartz, forging a new, long-term partnership built on reliability, efficiency, and shared success. For them, VinaQuartz became more than a supplier—we became a partner in their profitability.

This is the true meaning of a Partner for Growth.

Stop wasting time and materials with unreliable suppliers. Experience the VinaQuartz reliability.