Table of Contents

In the high-end surface industry, we are witnessing a fundamental transition. The era of “Standard Quartz” as a mere commodity is fading, replaced by a sophisticated market that demands two things: absolute safety and hyper-realistic aesthetics. For global distributors and OEM partners, staying competitive no longer depends on volume alone—it depends on the technological agility of their manufacturing partner.

Our commitment to providing the best materials includes Low Silica Quartz Slabs that meet rigorous safety standards.

At VinaQuartz, our R&D center serves as the bridge between these shifting market demands and industrial reality. We are not just following trends; we are re-engineering the very composition of engineered stone to ensure our partners remain at the forefront of the global supply chain.

The Path to Sustainability: Low Silica Quartz Slabs Innovation

The introduction of Low Silica Quartz Slabs significantly enhances the safety of work environments.

The most significant shift in the US and EU markets today is the movement toward safer working environments. Regulatory pressures regarding crystalline silica have transformed from a quiet conversation into a mandatory roadmap for survival.

Our laboratory has spearheaded a phased evolution in material composition:

- The Traditional Foundation: Maintaining the durability that made quartz a staple in global construction.

- Low-Silica Quartz Slabs Innovation: We have successfully optimized our formulas to reduce silica content, directly addressing the health and safety concerns of modern fabricators without compromising the slab’s structural integrity.

- The Zero-Silica Objective: Our current technical focus has shifted toward “Zero-Silica” solutions. This represents the pinnacle of surface safety, allowing our partners to import and distribute with zero scraping in highly regulated markets.

Elevating the Aesthetic: The Precision of Printed Quartz and Marble-Look

While safety is a regulatory necessity, aesthetics remain the primary driver for architects and designers. However, the market’s expectation for “Marble-Look” has evolved beyond simple surface patterns.

Low Silica Quartz Slabs not only provide safety but also offer unmatched aesthetics.

When selecting materials, Low Silica Quartz Slabs are a prime choice for their aesthetic and safety benefits.

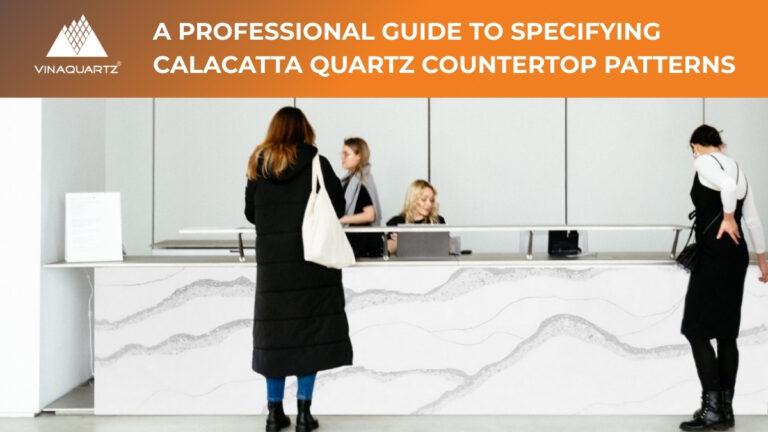

To meet this demand, VinaQuartz has integrated advanced Kreos® surface technology and Full-Body Printed systems. This is a critical leap in manufacturing capability. Unlike traditional methods that only apply a pattern to the top layer, our R&D team has perfected the ability to carry the “soul” of natural stone through the entire thickness of the slab. For a designer, this means edge profiles and mitered joins now maintain the continuity of the vein, providing the visual depth of natural marble with the superior performance of engineered stone.

Industrial Stability Through Vertical Integration

Our factory focuses on producing Low Silica Quartz Slabs that meet the highest quality standards.

A factory’s capacity to innovate is only as strong as its control over raw materials. Within the Nhat Huy Group ecosystem, VinaQuartz benefits from a unique “Vertical Integration” model that serves as our economic moat.

By working in direct synergy with Global Minerals, our R&D center controls the quality of CaCO3 powder at the source. This allows us to calibrate particle distribution and whiteness levels with extreme precision. For our OEM partners, this technical control translates into batch-to-batch consistency – a vital requirement for large-scale hospitality and residential projects where hundreds of slabs must match perfectly across multiple floors.

Discover VinaQuartz Factory

We are excited to showcase our latest innovations in Low Silica Quartz Slabs at the upcoming event.

Join us to explore the incredible possibilities with Low Silica Quartz Slabs at Coverings 2026.

Engineering the Future of Surfaces

Discover how Low Silica Quartz Slabs can transform your projects at our booth.

The modern surface market rewards the fast and the innovative. At VinaQuartz, our commitment to continuous improvement is evidenced by our R&D center’s ability to launch exclusive designs every month. We are not merely responding to the market; we are equipping our partners with the products that will define the next decade of interior design.

As we move toward Coverings 2026, we invite our global partners to witness these breakthroughs firsthand. From the safety of our Zero-Silica prototypes to the breathtaking depth of our latest Printed Quartz collections, the future of material science is already here.

Experience the evolution of VinaQuartz at Coverings 2026 Booth #8095 | Las Vegas Convention Center March 30 – April 2, 2026