Jumbo vs Regular Quartz Slabs — for a fabricator, every cut matters. The difference between a profitable project and a losing one often lies in material yield. What percentage of a valuable quartz slab ends up as waste in your workshop? This is not just a question of waste; it is a question of profit.

The long-standing debate between using Jumbo and Regular size slabs is central to this challenge. However, the discussion should not be about which size is “better,” but rather about which is smarter for a specific job. A true supply partner understands this distinction. They do not just sell a product; they provide a strategic solution that directly impacts your bottom line.

This article will analyze the practical applications of both slab sizes and explain how VinaQuartz’s flexible supply solution acts as a key advantage for fabricators in the US. This is what it means to be a true “Partner for Growth.”

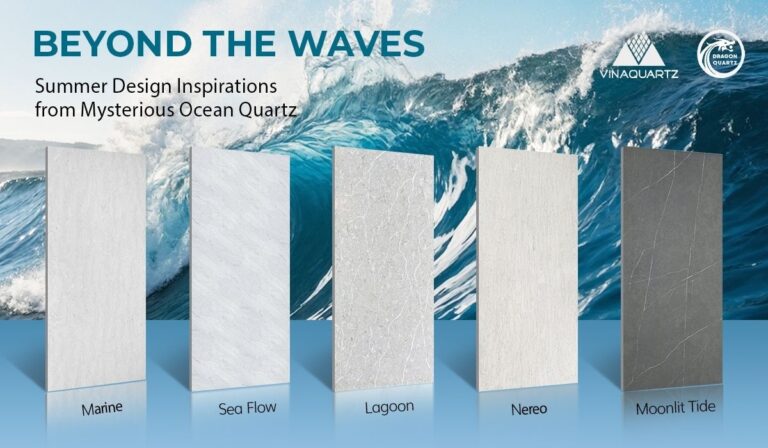

Understanding Regular Size Slabs – The Foundation of Flexibility

The Regular Size slab is the versatile workhorse of the fabrication industry, offering a balance of manageable dimensions and broad applicability for a variety of projects.

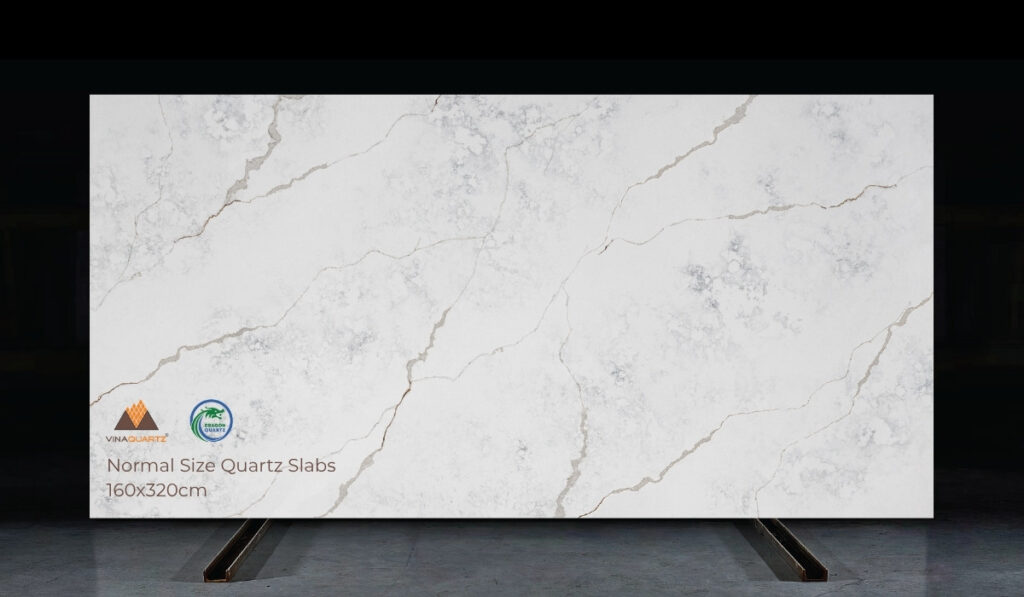

VinaQuartz Regular Size: 160x320cm

Regular Size slabs offer several practical advantages, particularly concerning cost and handling. A key benefit is that they are highly cost-effective for smaller jobs. For projects that require components like Vanity Tops, Bathroom Vanity Tops, or Backsplashes, using a Regular Size slab ensures you use only what you need, which minimizes expensive offcut waste. Furthermore, their easier handling is a significant operational benefit. The manageable dimensions and lower weight make these slabs simpler to transport, maneuver, and process, a valuable feature for workshops with limited space or handling equipment.

While versatile, the primary limitation of Regular slabs becomes apparent when dealing with larger surfaces, such as a wide Kitchen Island, where more seams are required.

The Power of Jumbo Size Slabs – Maximizing Aesthetics and Yield

On the other hand, Jumbo Size slabs are engineered to solve the limitations of their regular counterparts, offering distinct advantages in aesthetics and material optimization for larger-scale applications.

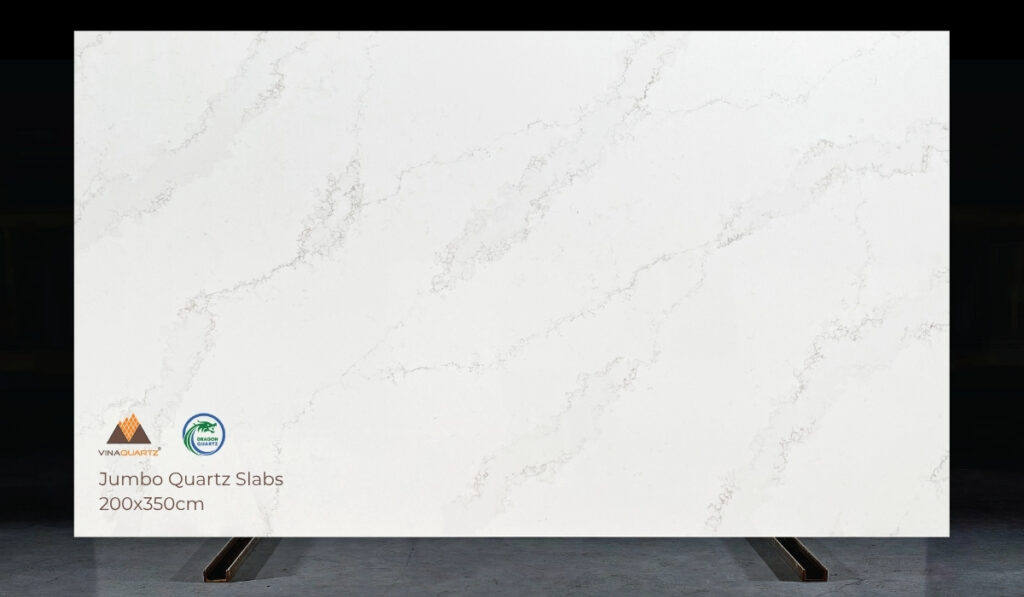

VinaQuartz Jumbo Size: 200x350cm

The most significant advantage of a Jumbo slab is the ability to deliver a seamless finish. This allows fabricators to create large surfaces, like a grand Kitchen Island or a long Countertop, with few or no seams, achieving the premium, monolithic look that clients increasingly demand. In terms of production, they provide a higher material yield on these large-scale projects. A fabricator can often cut all necessary components from a single Jumbo slab, which significantly reduces waste compared to fitting pieces onto several Regular slabs. This makes them the ideal choice for high-end Residential Housing and expansive Wall Cladding in Commercial Buildings.

The main consideration, of course, is that using a Jumbo slab for a small job can be inefficient and create unnecessary waste.

The Fabricator’s Dilemma: A Direct Comparison Between Jumbo vs Regular Quartz Slabs

A fabricator’s project pipeline is diverse. One day you are producing fifty identical Vanity Tops for a hotel; the next, you are crafting a custom, oversized Kitchen Island. Your material needs change constantly. To better illustrate this daily challenge, let’s compare the two sizes directly from a fabricator’s perspective.

| Criteria | Regular Size (160x320cm) | Jumbo Size (200x350cm) |

| Ideal Project | High-volume, smaller items: Vanity Tops, Backsplashes, Prefab. | Large, high-value items: Kitchen Islands, seamless Countertops. |

| Waste Optimization | High for small components. Low for large surfaces (more seams). | High for large components. Low for small jobs (creates more offcuts). |

| Operational Needs | Flexible, no special equipment needed. Suits any workshop size. | Requires space and specialized lifting equipment. |

| Economic Efficiency | Best for residential housing projects and hospitality contracts. | Best for high-end custom designs and commercial buildings. |

As the table clearly shows, a single-size inventory creates an unavoidable conflict between project needs and material efficiency. This operational gap is precisely where a strategic supply partner can make the difference between profit and loss.

The VinaQuartz Solution: The Strategic Advantage of “Mix-Size” Orders

VinaQuartz understands this challenge intimately. Therefore, we do not force you to choose. Instead of a rigid, one-size-fits-all approach, we provide a flexible and intelligent solution designed for the reality of your business: the “Mix-Size” order.

This unique capability means you can combine both Regular and Jumbo slabs in the same order. This is more than just a feature; it is a fundamental business solution. It allows you to order the exact materials you need for your current projects, reducing inventory risk and improving your cash flow. For fabricators of all sizes, this flexibility is a significant competitive advantage.

Case Study: How a Canadian Fabricator Increased Profitability by Switching Partners

To see this solution in action, let’s look at a real-world success story from our work with a partner in Canada.

The situation began when a leading fabricator was seeking a new supply partner, driven by a need for more consistent product quality and greater operational flexibility. Their production workflow presented a specific and complex challenge. The company required Regular Size slabs for their detailed work with VinaQuartz’s specialized Printed Quartz Slab products, while also needing Jumbo Size slabs for larger countertop projects to optimize material yield and minimize waste. This dual requirement made sourcing from a single supplier difficult and inefficient.

In response, VinaQuartz approached them not simply as a seller, but as a solutions provider. We analyzed their workflow and proposed our unique “mix-size” order, a tailored shipment that included both the Regular Size Printed Quartz Slabs and the Jumbo Size slabs they needed. This single order was designed to precisely match their production requirements.

The impact of this tailored solution was immediate and significant. By aligning their material supply directly with their fabrication needs, the company dramatically reduced material waste, increased production efficiency, and directly improved their profit margins. This success transformed the relationship from a simple transaction into a strategic partnership, perfectly illustrating VinaQuartz’s commitment to being a “Partner for Growth.”

See How VinaQuartz Produce High-Quality Quartz Slabs here

A Smarter Partnership for a More Profitable Business

In conclusion, the strategic choice for the modern fabricator is not Jumbo or Regular; it’s having a partner who can provide Jumbo and Regular. Flexibility in your supply chain is a direct path to profitability.

At VinaQuartz, we are committed to your growth. Our “mix-size” capability is just one example of how we provide more than just quartz slabs—we deliver business solutions that help you thrive in a competitive market.

Is material waste impacting your bottom line? Talk to our experts about our “mix-size” supply solution, designed specifically for fabricators.

Discuss a mix-size supply solution with our experts.