The materials we choose to adorn our spaces speak volumes about our aesthetic preferences and functional needs. As the demand for unique, durable, and aesthetically pleasing materials grows, the interior design industry continuously seeks innovations that push the boundaries of creativity and practicality. One of the latest breakthroughs in this arena is Full Body Printed Quartz, an engineered stone that combines the robustness of quartz with the advanced capabilities of high-resolution digital printing technology. This innovative material is setting new standards in design flexibility and material performance, offering vast possibilities for both residential and commercial environments.

Understanding Full Body Printed Quartz

Full-body printing technology for quartz slabs is a highly advanced process that requires significant investment in equipment, expertise, and facilities.

You can learn more about our full-body printing technology here.

Therefore, only companies with a certain scale and capacity can effectively implement this technology. Here’s a breakdown of what kind of enterprises can adopt full-body printing:

1. Large-Scale Manufacturing Enterprises

Full-body printing technology is most accessible to large-scale manufacturers in the quartz and stone processing industry. These companies typically have:

- Advanced Machinery: Full-body printing requires specialized equipment, including high-resolution digital printers and industrial compaction tools, which are often expensive.

- R&D Departments: Large manufacturers often have research and development teams capable of handling the technical complexities involved in the production of full-body printed quartz slabs.

- High Production Capacity: This technology suits companies that can produce in bulk and handle large orders while maintaining high-quality control. Businesses with a global reach and high production volume can justify the investment in this technology.

2. Companies Focused on Innovation and Customization

Businesses that prioritize innovation and customized designs are well-suited for this technology:

- Interior Design Firms with In-House Production: High-end design companies that produce their materials or collaborate closely with quartz manufacturers may invest in this technology to offer customized, exclusive products to their clients.

- Luxury Material Suppliers: Companies that supply to the luxury market, where aesthetics and customization are critical, can benefit from full-body printing. They can offer premium products with the natural stone look at a lower cost while providing unique design options.

3. Businesses Focusing on Sustainability and Health Compliance

Full-body printed quartz often uses low silica materials, which comply with stricter health and safety regulations. Companies that emphasize sustainability and worker safety will find value in adopting this technology:

- Sustainable Construction Material Manufacturers: Companies focused on producing eco-friendly and safe building materials can use full-body printing to offer low-silica products that reduce health risks, ensuring they meet environmental standards.

- Corporations in Regulated Markets: In regions like the U.S. or Europe, where silica dust regulations are strict, large manufacturers needing to comply with OSHA or EU standards can implement this technology to stay competitive.

4. Medium-Sized Enterprises with Investment Potential

Medium-sized businesses that are financially robust or have access to investment capital can also adopt this technology. Although the initial investment is significant, companies looking to expand their product range and attract premium clientele can benefit from the long-term returns of offering full-body printed quartz:

- Strategic Partnerships: Some medium-sized companies may enter joint ventures or form partnerships with larger manufacturers to access the technology without making a full upfront investment.

5. Specialized Niche Markets

Smaller, niche manufacturers that cater to high-end custom projects or bespoke interior design markets can also implement full-body printing if their business model allows for higher product margins:

- Artisan Design Studios: Studios offering high-end custom slabs for unique architectural or design projects can adopt the technology to create limited edition or one-of-a-kind designs for luxury spaces.

What is Printed Quartz?

Full Body Printed Quartz is a type of engineered stone that utilizes digital printing technology to apply detailed designs and colors directly onto quartz surfaces. Unlike traditional manufacturing processes that might embed a pattern only on the surface, the full body technique extends these intricate designs throughout the entire depth of the slab. This ensures consistency in appearance across all dimensions of the material, making it ideal for comprehensive architectural and design applications.

The technology behind this innovation involves layering digital images onto quartz slabs using specialized high-resolution printers capable of delivering up to 720×1800 dpi. This allows for the reproduction of high-fidelity images that can range from realistic depictions of natural stone to elaborate, custom-designed patterns.

Technological Innovations in Material Fabrication

The cornerstone of Full Body Printed Quartz’s appeal is its manufacturing process, which incorporates the latest advances in digital printing technology. These high-tech printers use durable inks designed to penetrate deep into the quartz, ensuring that the designs are not only surface-level but are also embedded within the body of the material. The result is a product that maintains its visual integrity even when cut or shaped, a critical consideration for kitchen countertops, bathroom vanities, and other custom-fabricated installations.

Additionally, this technology allows for an unprecedented level of design customization. Designers and homeowners can select from a vast array of existing patterns or commission bespoke designs that reflect their unique style and décor preferences. Whether the objective is to mimic the elegant veining of marble or to create a vibrant, contemporary pattern, Full Body Printed Quartz can accommodate virtually any design specification.

Vinaquartz, a quartz slab manufacturer supplying the U.S. market since 2010, continues to innovate by expanding into printed quartz to meet the rising demand for customization and aesthetic versatility in interior design. By developing low silica, eco-friendly products, Vinaquartz ensures compliance with stringent safety regulations and positions itself as a leader in the industry. Now partnering with Dragonquartz, Vinaquartz has not only focused on the quartz fabrication line but also diversified its offerings with printed quartz, providing more unique stone vein designs. This continuous innovation enhances their competitive advantage, allowing them to cater to premium customers and provide effective alternatives to increasingly scarce natural stones like marble, while strengthening their supply chain expertise.

Bio Quartz: Enhancing Material Quality and Safety

A significant innovation in Full Body Printed Quartz is the use of Bio Quartz as its base material. This enhanced quartz variant reduces the silica content traditionally found in natural quartz. High silica content can pose health risks during cutting or sanding, releasing harmful particles into the air. By lowering silica levels, Bio Quartz not only makes the installation process safer but also enhances the overall quality and clarity of the printed designs. This clarity is crucial for accurately translating intricate digital images onto the quartz slabs, ensuring sharp, vivid patterns that are both aesthetically pleasing and highly detailed.

The Bio Quartz also contributes to the material’s durability, offering greater resistance to scratches and impacts. This makes Full Body Printed Quartz an excellent choice for high-traffic areas such as commercial settings, where both appearance and longevity are key considerations.

Environmental Considerations and Sustainability

In today’s eco-conscious world, the sustainability of building materials is increasingly important. Full Body Printed Quartz addresses this concern by offering a product that is not only durable and long-lasting but also safer and less wasteful than some traditional materials. The digital printing process reduces waste by using only the necessary amounts of ink to create designs, contrasting with the potentially wasteful practices involved in traditional stone quarrying and manufacturing. Furthermore, the durability of Full Body Printed Quartz means less frequent replacements, contributing to a reduction in material consumption over time.

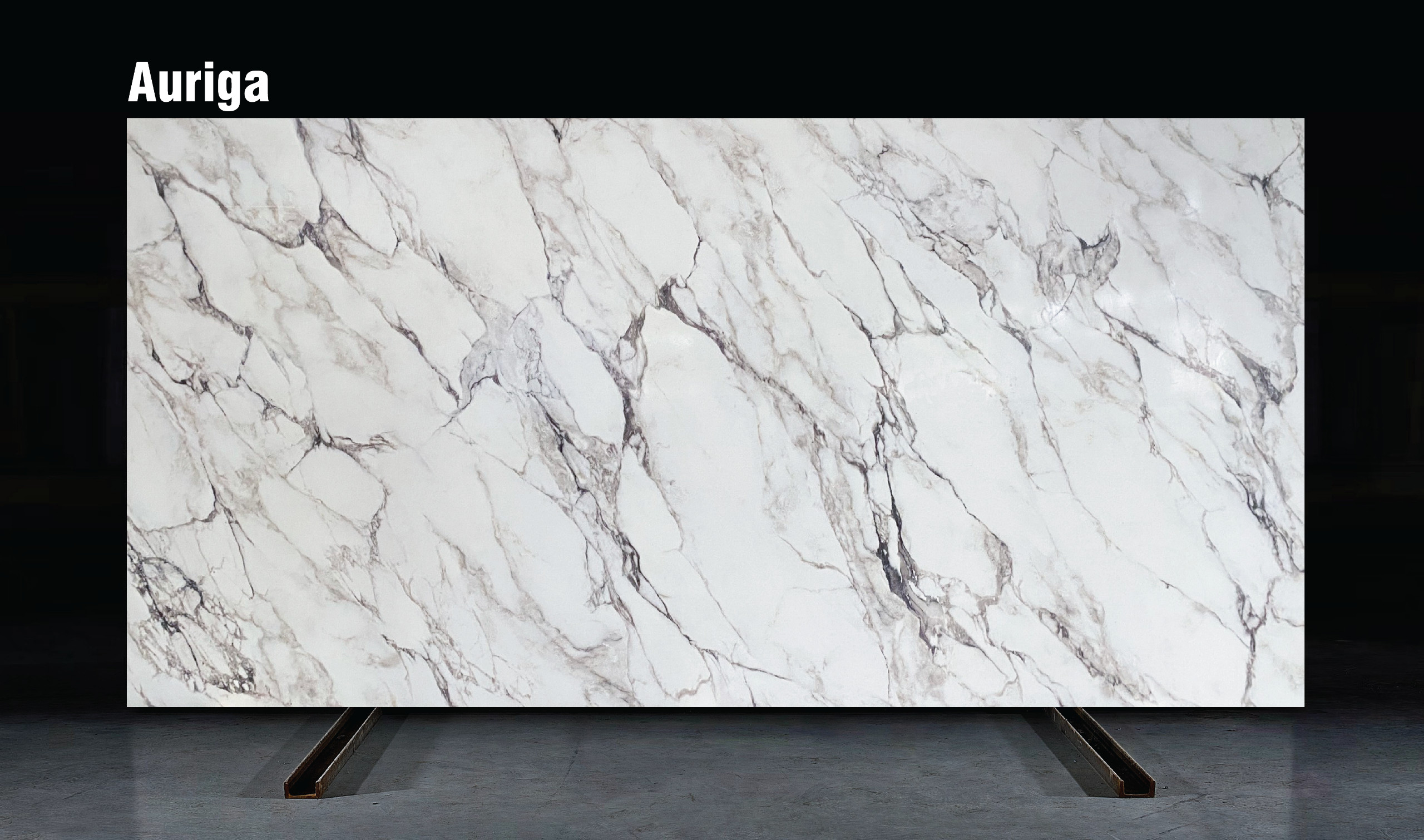

Introducing Our Newest Printed Quartz: L’Univers Collection

The versatility of Full Body Printed Quartz makes it suitable for a wide array of applications. In residential settings, it is perfect for countertops, flooring, and wall claddings. Its resistance to stains, scratches, and moisture makes it ideal for kitchens and bathrooms. In commercial spaces, the material can be used for bar tops, reception desks, and high-impact wall features, where durability and visual impact are paramount.

Moreover, the ability to customize patterns and colors allows Full Body Printed Quartz to align with any design theme, from classic elegance to modern minimalism. This flexibility is invaluable for designers seeking to create cohesive interiors that reflect specific branding or stylistic themes.

The Future of Full Body Printed Quartz

As Full Body Printed Quartz continues to gain popularity, its potential applications and innovations seem limitless. With advancements in digital printing technology, we can anticipate even higher resolutions and more detailed imagery. Additionally, as the market for this material grows, there may be opportunities to explore new base materials and enhance environmental benefits, further cementing Full Body Printed Quartz as a key player in the future of interior design materials.

In conclusion, Full Body Printed Quartz represents a significant leap forward in the field of engineered surfaces. Combining the time-tested durability of quartz with the latest in digital printing technology, it offers a solution that meets the dual demands of beauty and functionality. As this material becomes more integrated into both residential and commercial projects, it promises to continue revolutionizing the possibilities of interior design, making it an exciting time for designers, architects, and homeowners alike.

Explore more about Vinaquartz Factory

Immer Yourself In The Most Stunning Calacatta Quartz Slabs for 2024 Picked by Vinaquartz