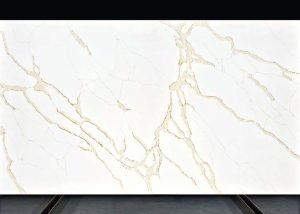

Marine

The Serene Beauty of Marine from the Mysterious Ocean Collection

Ideal for those seeking to infuse their environments with a natural, calming aesthetic, Marine combines the timeless durability of quartz with the ethereal beauty of the sea. Whether you are designing a modern home or a sophisticated commercial space, Marine provides a foundation of elegance and tranquility.

Description

The Serene Beauty of Marine from the Mysterious Ocean Collection

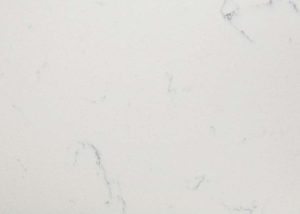

Introduce a touch of oceanic serenity into your space with Marine, a key highlight of our Mysterious Ocean collection. This Quartz slab features a soft, pale gray base interwoven with delicate, subtle veins that mimic the gentle undulations of calm sea waves.

Marine’s surface effect brings a light, airy feel to any interior, evoking a quiet ocean’s tranquil and soothing presence. The soft gray tones blended with the smooth, flowing lines offer peace and expansiveness, perfect for creating a serene backdrop in any setting.

Ideal for those seeking to infuse their environments with a natural, calming aesthetic, Marine combines the timeless durability of quartz with the ethereal beauty of the sea. Whether you are designing a modern home or a sophisticated commercial space, Marine provides a foundation of elegance and tranquility.

Additional information

| Normal Size | 160x320cm |

|---|---|

| Jumbo | 200x350cm |

| Vein color | White and Dark Grey |

| Background color | Grey |

| Collection | Mysterious Ocean Collection |